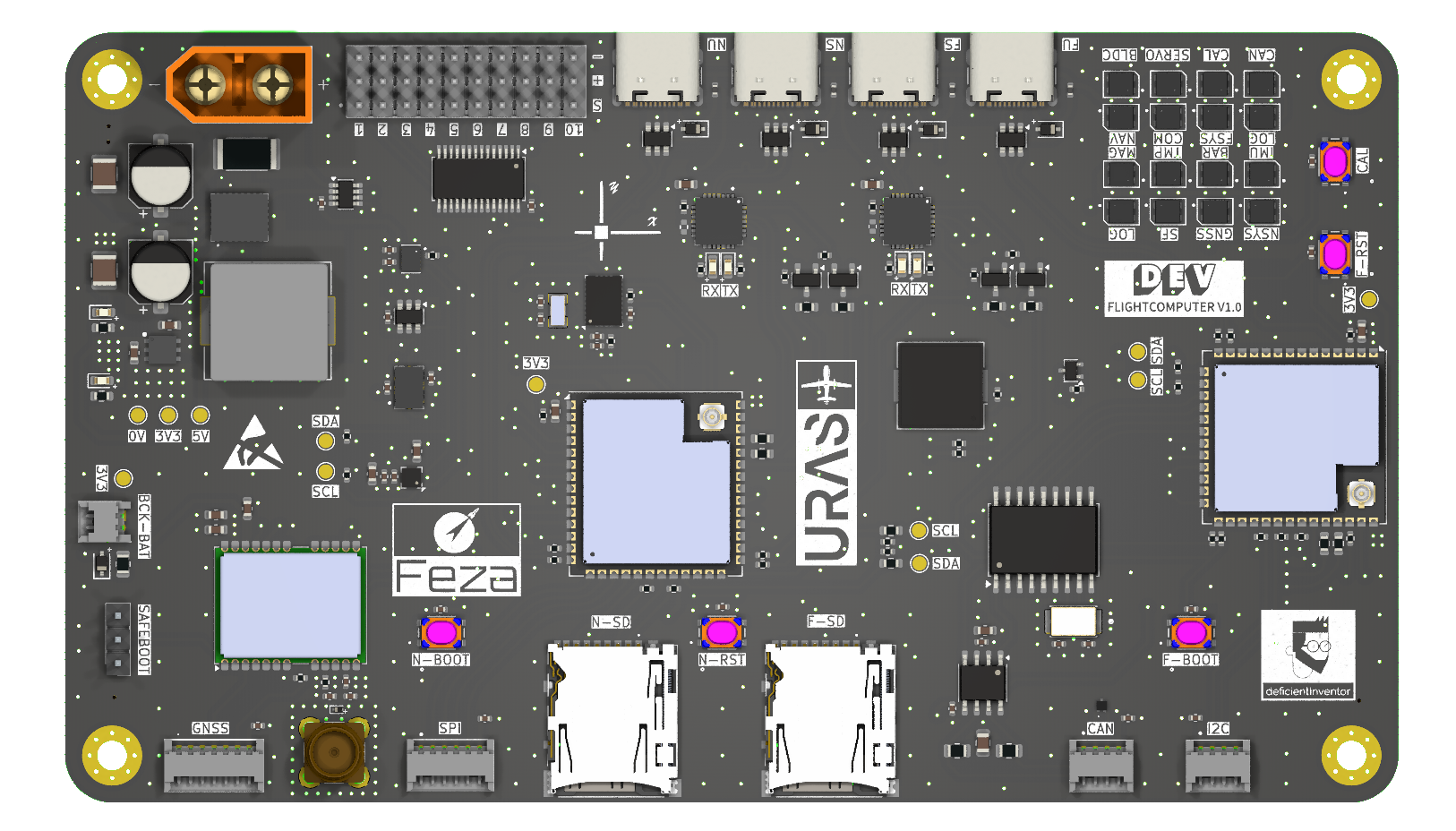

DEV Flightcomputer V1.1 (REV1)

Revision 1 documentation.

- You can easily navigate through the contents navigation bar on the right side.

- If you want to read about the design choices and overall system design, click here 🚀.

Revision Changelog

Change 1

Description:

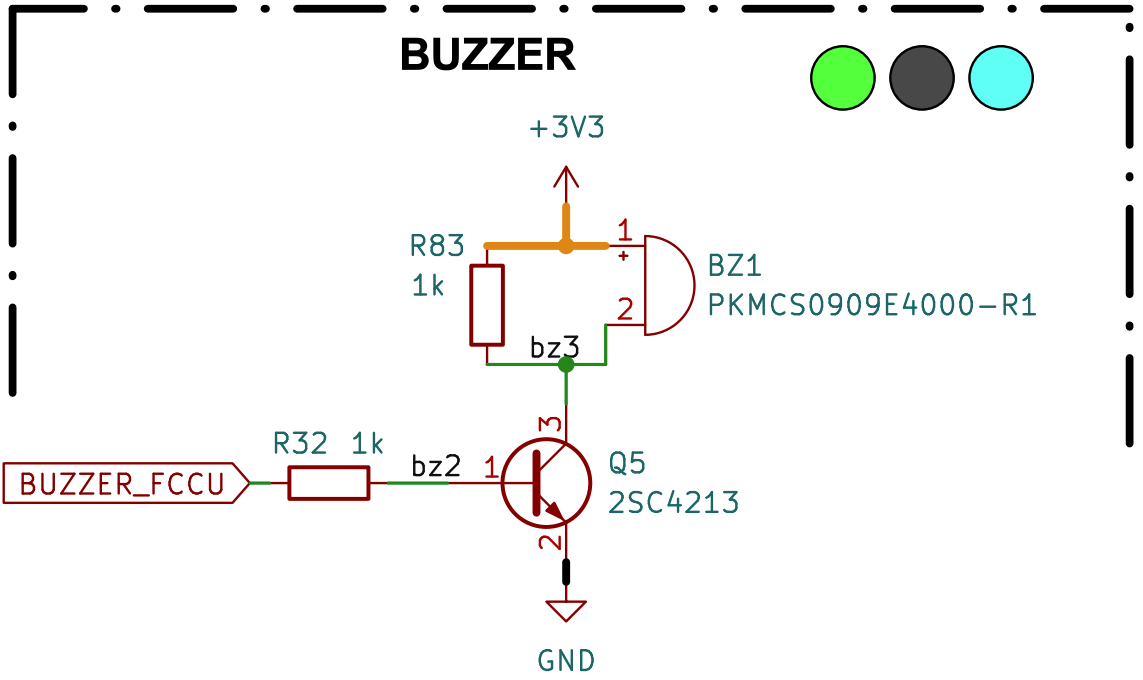

A transistor and two 1kΩ resistors were added to the buzzer circuit to protect the ESP32 and provide better control over the buzzer.

Changes:

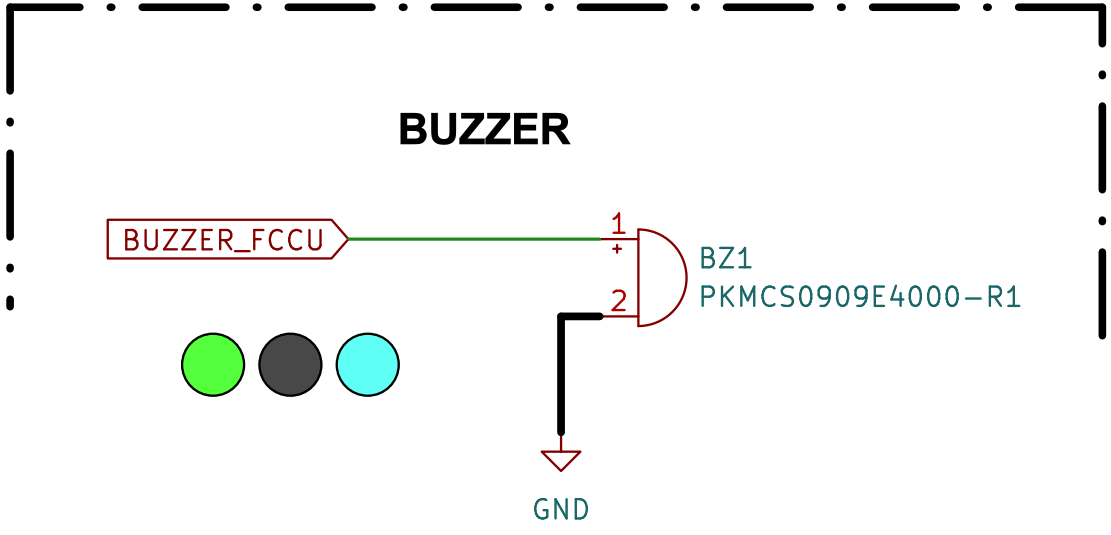

Before (Rev0):

The buzzer was directly connected to the ESP32 GPIO pin, which could lead to potential overload or insufficient control.

After (Rev1):

A transistor is now used to decouple the buzzer’s current path. Two 1kΩ resistors were added: one as a base resistor to limit the current to the transistor and another to control the buzzer’s operating current.

Improvements:

- ESP32 Protection: Prevents GPIO pin overload by offloading the buzzer’s current through the transistor.

- Improved Control: Ensures reliable switching of the buzzer with the transistor acting as an intermediary.

- Signal Stability: Controls the base current with a dedicated resistor, ensuring stable transistor operation and protecting the control circuit from malfunctions.

Change 2

Description:

Proper length matching of USB D+/D- lines is essential to ensure signal integrity and reliable communication. Adjustments were made to address trace length differences and optimize routing.

Calculation:

Parameters:

- \(L_{\text{Diff}}\): Maximum length difference between the traces (e.g., in mm or inches).

- \(S_{\text{Limit}}\): Skew limit in time (e.g., in ps or ns).

- \(\tau_{\text{Delay}}\): Delay per unit length.

- \(v_{\text{Signal}}\): Signal velocity in m/s.

- \(c\): Speed of light in a vacuum (\(3 \times 10^8 \, \text{m/s}\)).

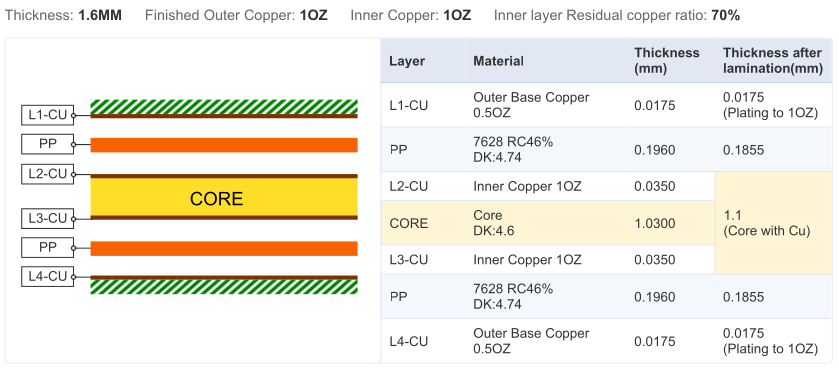

- \(D_k\): Relative dielectric constant (FR4).

Combining the Formulas:

1st Substituting: \(\tau_{\text{Delay}} = \frac{1}{v_{\text{Signal}}}\) into the formula for \(L_{\text{Diff}}\):

\[L_{\text{Diff}} = S_{\text{Limit}} \times v_{\text{Signal}}\]2nd Substituting: \(v_{\text{Signal}} = \frac{c}{\sqrt{D_k}}\) into the formula for \(L_{\text{Diff}}\):

\[L_{\text{Diff}} = S_{\text{Limit}} \times \frac{c}{\sqrt{D_k}}\]Example:

Given:

\(S_{\text{Limit}} = 100 \, \text{ps} = 100 \times 10^{-12} \, \text{s}\)

\(D_k = 4.74\)

\(c = 3 \times 10^8 \, \text{m/s}\)

Calculation:

Result:

The maximum length difference \(L_{\text{Diff}}\) for a skew limit of 100 ps and \(D_k = 4.74\) is approximately 13.78 mm. This value includes the USB-Cabels and other PCBs.

Changes:

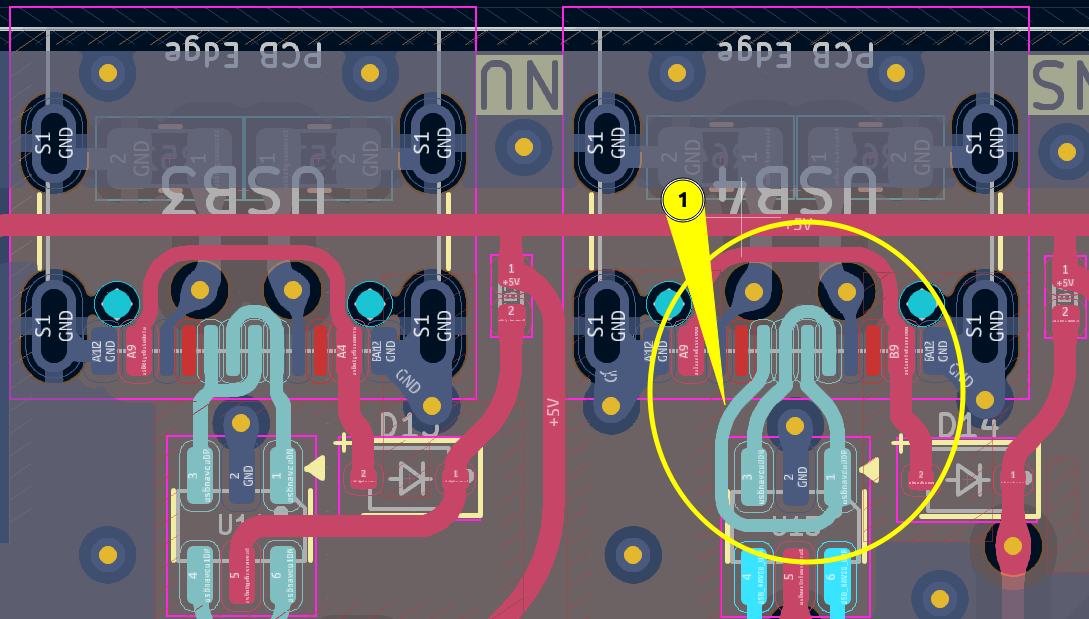

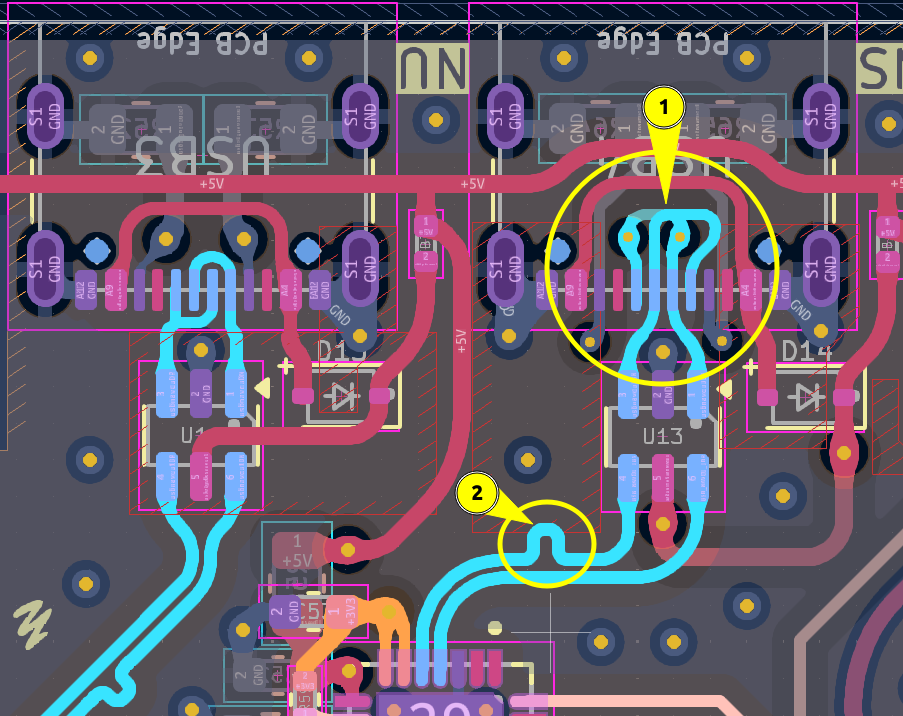

Before (Rev0):

One of the USB data lines had a 5mm longer trace and was routed underneath the ESD protection chip to avoid using vias. This length difference could result in signal degradation and timing mismatches.

After (Rev1):

Vias are now used to route the USB data lines, reducing the length difference to just 1mm and achieving proper length matching. This change ensures compliance with high-speed USB design guidelines.

Improvements:

- Signal Integrity: The improved length matching enhances USB signal quality and minimizes timing issues, ensuring more reliable communication.

- Reliability: The routing adjustments maintain the effectiveness of the ESD protection chip while avoiding potential signal disruptions.

- Performance: By adhering to USB length matching requirements, the design supports high-speed data transmission with reduced risk of errors.

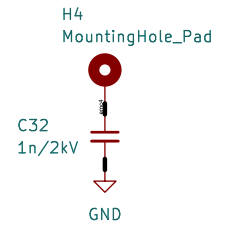

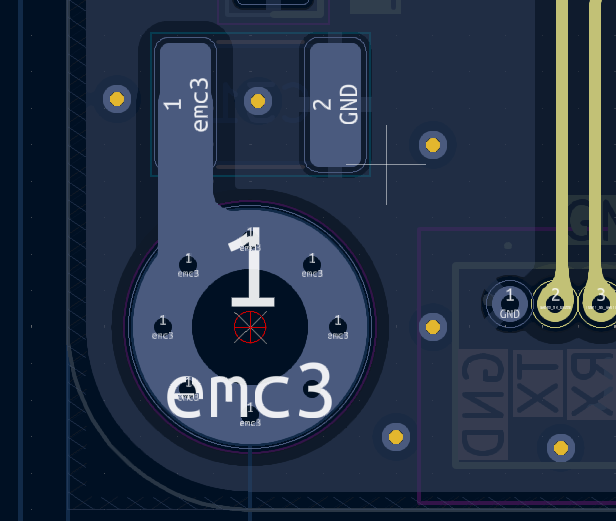

Change 3

Description:

Added 1nF/2kV capacitors to each mounting point (Electromagnetic Compatibility).

Changes:

Improvements:

- Improved electromagnetic compatibility (EMC) and protection against external interference by adding 1nF/2kV capacitors to the mounting points. This helps reduce the impact of high-frequency noise and enhances the overall stability of the system.

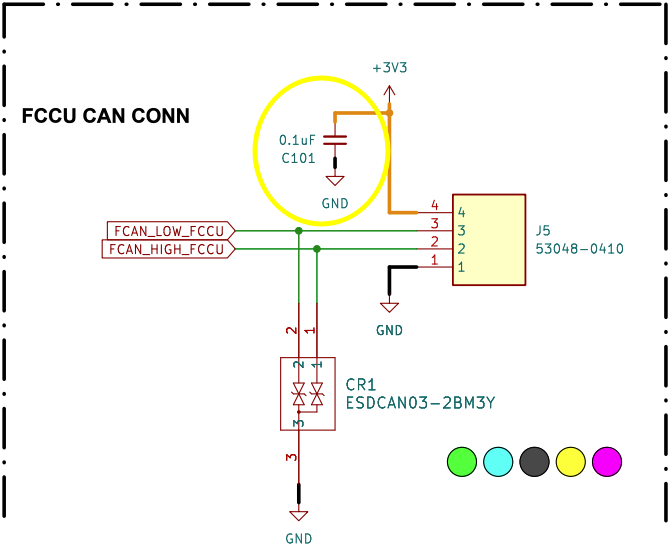

Change 4

Description:

Added 100nF capacitors to all board-to-wire connectors.

Changes:

Before (Rev0):

No capacitors for the outgoing 3.3V pins of the board-to-wire connectors.

Improvements:

- Enhanced stability and noise reduction by adding 100nF capacitors to all board-to-wire connectors. This modification helps in filtering high-frequency noise and stabilizing the voltage supplied to the connected components.

Change 5

Description:

Updated the impedance calculations for the RF traces (GNSS).

Changes:

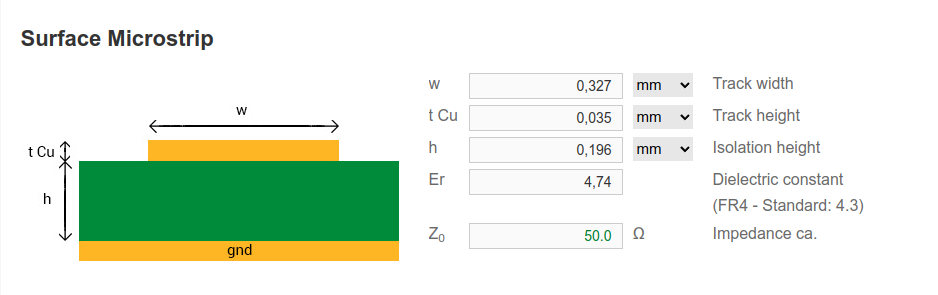

Before (Rev0):

Microstrip 50Ω Trace Width: 0.327 mm (calculated)After (Rev1):

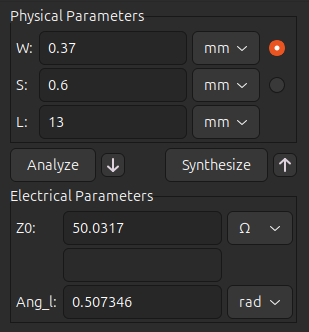

Coplanar Waveguide with Ground Plane 50Ω Trace Width: 0.37 mm (calculated)

Improvements:

- The coplanar waveguide (CPW) design is generally better for RF traces. In this revision, I corrected my previous mistake, where I had designed the trace as a CPW-WG but mistakenly calculated the impedance as if it were a microstrip. go to calculation🧮

Schematic

- You can access the PDF via the attached link or the PDF viewer.

Schematic Colored

Schematic Monochromatic

Trace’s / Impedance / Board

Power

| TraceID | TraceWidth (mm) |

|---|---|

| VBAT | 2.5 |

| +5V | 0.5-2.5 |

| +3V3 | 0.5 |

| REG_FB | 0.35 |

| GND | 0.5-4 |

Signal

| TraceID | TraceWidth (mm) | Spacing (mm) | Impedance (Ω) |

|---|---|---|---|

| SPI | 0.327 | 0.6 | 50 |

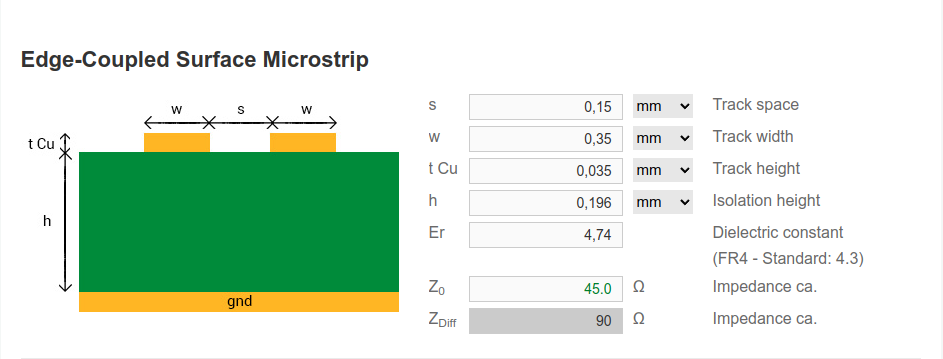

| USB | 0.35 | 0.15 | 90 |

| UART | 0.327 | 0.6 | 50 |

| I2C | 0.327 | 0.6 | 50 |

| SIGNAL | 0.327 | 0.6 | 50 |

| RF | 0.37 | 0.6 | 50 CWG w/ Ground |

Calculations

50 Ω Coplanar Waveguide w/ Ground

50 Ω

90 Ω

Board

| Boardfinish | ENIG |

| Tented Vias | YES |

Gerbers as SVGs / ZIP

- For better visibility, open the SVGs in a new tab by right-clicking and selecting Open pic in new tab.

Layer 1 (SIG)

Layer 2 (GND)

Layer 3 (PWR)

Layer 4 (SIG)

Gerber Viewer & Download

- To use tracespace.io, click the settings wheel and set the use outline layer for board shape GAP FILL LIMIT to 0.25mm for an error-free board view.

Fabrication Document

Assembly Document

Bill of Material

Interactive BOM

- In case you prefer to use the fullscreen iBoM, you can acces it via the Settings Gear.

Costs

| Item | Price |

|---|---|

| Components | 150,27€ |

| PCB Manufacturing | 106,51€ |

| PCB Assembly | 29€ |

| TOTAL | 285,78€ |

pie

title Cost Breakdown

"Components: 150,27€" : 150.27

"PCB (5): 106,51€" : 106.51

"Assembly (1): 29€" : 29

Reports

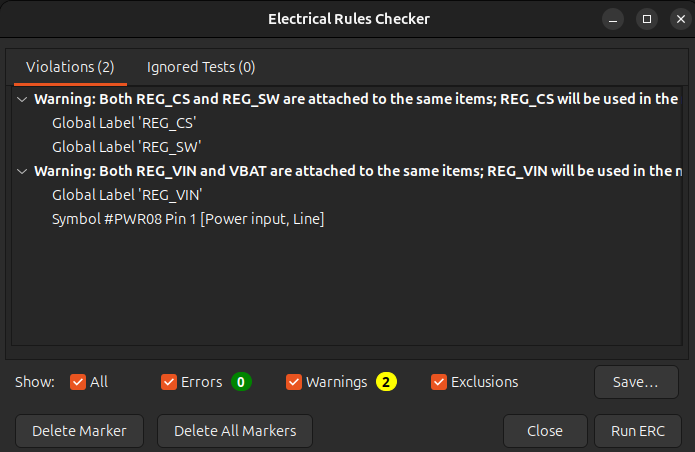

- The warnings from the ERC are known and occur due to the INA219 Current Sensor but the connections are right.

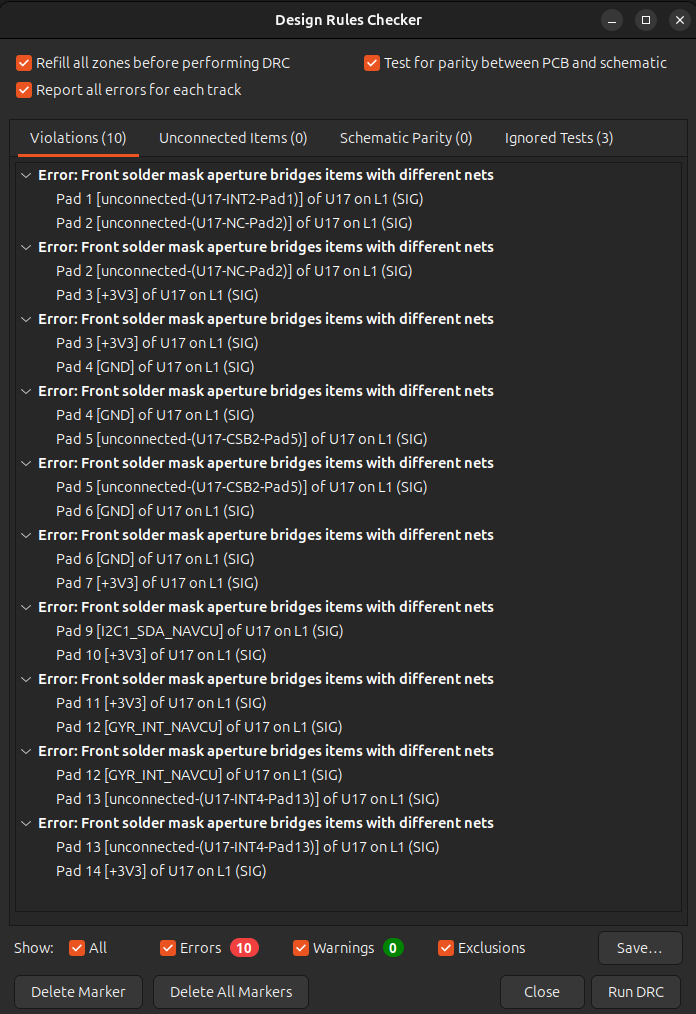

- The DRC Errors are known and it is due to the packagesize of the BMI088 (U17).

ERC

DRC

- 0 Errors if -> /File/Board Setup/Board Stackup/SolderMask&Paste/Allow bidged solder mask apertures between pads withing footprints

Known Issues

- TBD

Feel free to contact me if you notice any mistakes!